Chemo-enzymatic conversion of biomass into bio-ethanol

Abstract

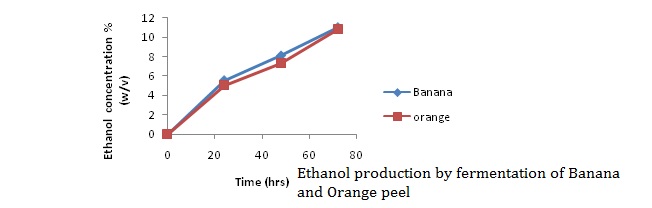

The energy crisis and environmental pollution from use of fossil fuels have become more serious globally which insisted us to explore the use of bio-fuels as cheaper and cleaner alternatives to fossil fuels. The higher production costs of alcohol, however, are an obstacle to the production of this energy source. Selection of biomass with higher yields and higher sugar content and at lower cost is, therefore, essential to cut down costs of ethanol production. In the present research we have taken fruit peels (orange and banana) as a substrate for the production of ethanol by some chemo-biological methods. Saccharomyces cerevisiae was taken for the fermentation and then the distillation we could recover 10-11% ethanol concentration. It has various advantages over the traditional fuel. It is biodegradable, low in toxicity and causes little environmental pollution if spilt. Bio-ethanol has higher octane number, broader flammability limit, higher flame speed and higher heat of vaporization than gasoline. It is much cleaner and releases no toxic gases.

Keywords

Full Text:

PDFReferences

N. Verma, Bioethanol from biomass: Review. Journal of Biofuel. 2010, 1(2), 245-256.

R. Harun, M. K. Danquah, G. M. Forde, Microbiological Biomass as a Fermentation Feedstrock for Bioethanol Production. Journal of Chemical Technology and Biotechnology. 2010, 85(2), 199-203.

D. P. Singh, R. K. Trivedi, Production of Biofuel from Lignocellulosic Biomass.International Journal of Applied Engineering Research. 2012, 7 (11), 2713-2719.

N. Saibani, S. Ghazvini, M. R. Andalibi, S. Yaghmaei, World Academy of Science, Engineering and Technology, 2011, 59, 1836.

Vogelbusch, Building a Bridge to the Corn Ethanol Industry, NREL Subcontract ZXE-9-18080-01. U.S.A., Houston, 2000, January 10.

S. S. Dhillon, R. K. Gill, S. S. Gill, M. Singh, Studies on the utilization of citrus peel for pectinase production using fungus Aspergillus niger. International Journal of Environmental Studies, 2004, 61(2), 199-210.

L. R. Lynd, Overview and evaluation of fuel ethanol from cellulosic biomass: technology, economics, the environment, and policy. Energy Environment. 1996, 21, 403-465.

Y. Lin, S. Tanaka, Ethanol fermentation from biomass resources: current state and prospects. Appl Microbiol Biotechnol. 2006, 69, 627-642.

D. J. Hayes, An examination of biorefining processes, catalysts and challenges. Catalysis Today, 2009, 145, 138-151.

G. L. Miller, Use of dinitrosalicylic acid reagent for determination of reducing sugar Analytical Chemistry. 1959, 31(3), 426-428.

M. Ballesteros, J. M. Oliva, M. J. Negro, P. Manzanares, I. Ballesteros. Ethanol from lignocellulosic materials by a simultaneous saccharification and fermentation process (SFS) with Kluyveromyces marxianus CECT 10875. Process Biochemistry, 2004, 39 (12),1843-1848.

Y. Sun, J. Cheng, Hydrolysis of lignocellulosic materials for ethanol production: a review, Bioresource Technology, 2002, 83, 1-11.

J. Singh. Effect of heavy metals and sewage on seed germination and plant growth. Int. Arch. Sci. Technol., 2006, 6(1), 1-4.

J. Singh. Determination of DTPA extractable heavy metals from sewage irrigated fields and plants. J. Integr. Sci. Technol., 2013, 1(1), 36-40.

T. Arif, B. Sharma, A. Gahlaut, V. Kumar, R. Dabur. Anti- diabetic agents from medicinal plants: A review. Chem. Biol. Lett., 2014, 1(1), 1-13.

ISSN 2321-4635

ISSN 2321-4635